Description

The Problem: Corrosive Water, Expensive Damage

Produced water is nasty stuff—filled with chemicals that eat gear alive. Especially unions.

Operators are stuck replacing components over and over again, dealing with:

- Stress cracking

- Pitting and localized corrosion

- Safety hazards

- Unplanned downtime

- $100K+ annual replacement costs (per stack)

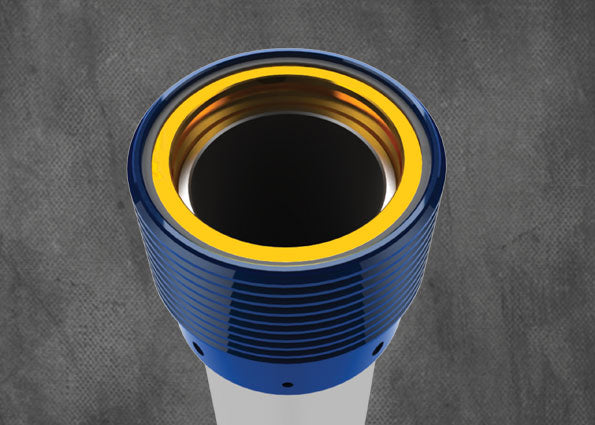

The Solution: CFC

The Corrosion-Free Connection (CFC) isolates bore fluids, keeps corrosive elements off your pressure-critical gear, and shuts down every dominant form of corrosion in the playbook.

What Makes It Different

Isolates bore fluids

Only corrosion-proof materials touch the fluid

Stops corrosion at the source

Handles chemical, electrochemical, and localized attacks

Built for H2S, high-temp, and produced water environments

No measurable material loss during trial testing

Easily integrates into existing stacks

No overhaul required

Backed by lab results and field trials

Including a West Texas case study

Zero replacements required in over two months of hard use

Projected lifespan?

5+ years

Case Study: West Texas

In one trial, operators running produced water through a lubricator stack saw zero measurable corrosion on the CFC after two months, compared to traditional unions that needed replacing up to five times a year.

- Annual savings:

$108,000 per stack - Replacements needed

Zero - Material loss

None - Projected service life

Over 5 years

That’s real-world durability. Real cost savings. And fewer headaches on your side of the job.

Easy to Add and Hard to Beat.

FHE’s Corrosion-Free Connection is built to slot into your existing equipment, minimize maintenance, and stand up to the kind of fluid profiles most gear can’t handle. It’s not some lab-born gimmick, it’s been proven in the field, under pressure, in the kind of jobs where nothing less than bulletproof will do.

Ask about the CFC and how it fits into your pressure control stack.

We’ll help you stop the damage before it starts and keep your crew running longer, safer, and smarter.