Description

What FracLock Does Different

- Keeps Your Crew Safely Out of the Danger Zone

With remote operation and pressure-locked safety mechanisms, FracLock means your team doesn’t need to be near the wellhead. Fewer injuries, less stress, and more time focused on the job—not the hazard.

- Slashes Setup and Tear-Down Time

Forget two-day rig-ups and scrambling for manifolds. FracLock is ready when the trucks roll in and gets to work fast. It’s an integrated system that trims fat, shaves hours, and lets your team do more stages in a day with fewer hands on deck.

- Replaces Overbuilt Iron with FHE Smart Design

FracLock eliminates over 85% of wellhead iron. Less equipment on-site means fewer points of failure, less maintenance, and faster inspections—all while creating more space and better access to the wellhead.

- Cuts Costs and Lifts Output

Fewer people. Less equipment. Less downtime. Add that up, and you’re looking at serious savings—without cutting corners. FracLock lets your operation scale up while keeping overhead tight.

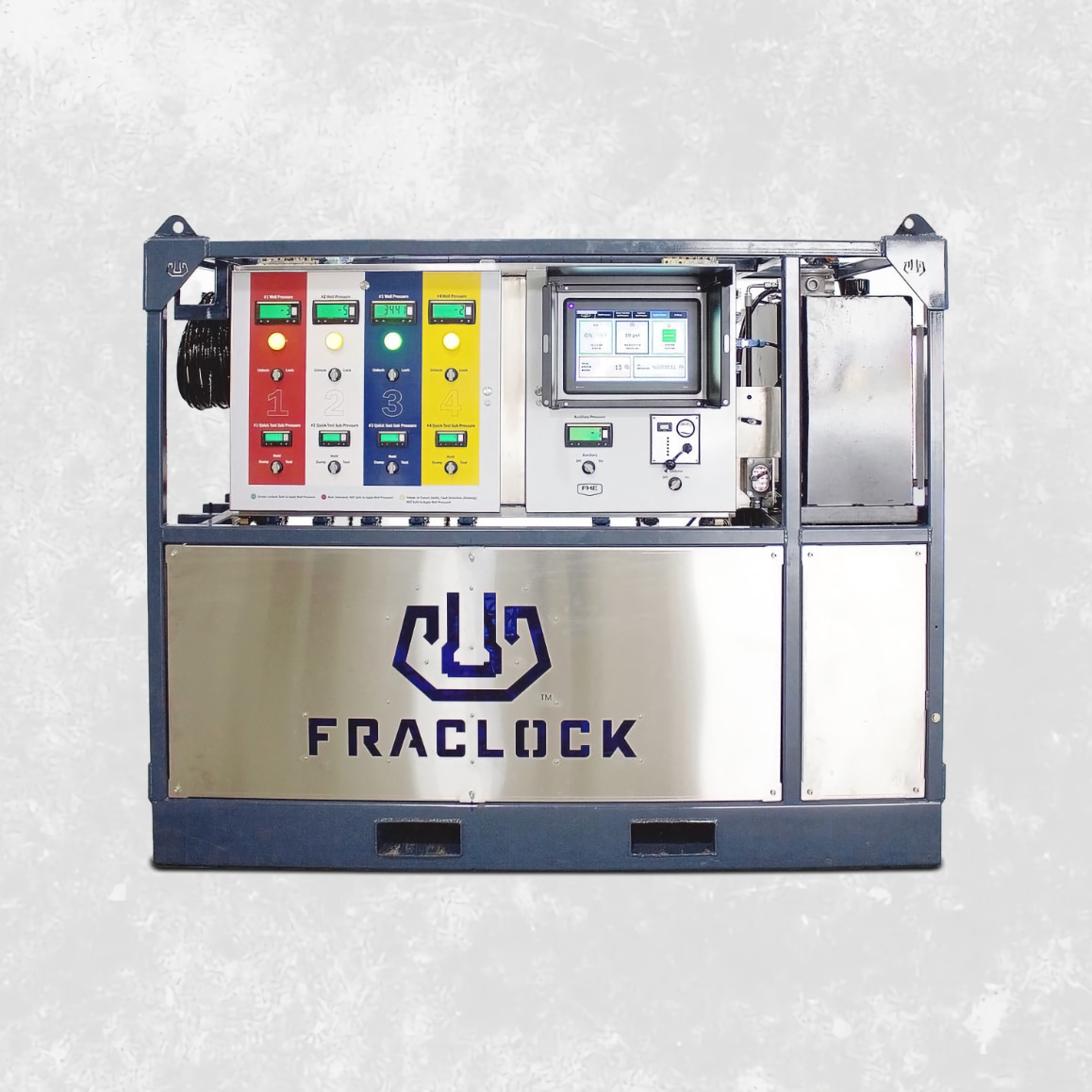

Control Unit

Everything You Need to Know. Right in Front of You.

The FracLock Control Unit puts the entire system at your fingertips, with real-time feedback, pressure monitoring, and safety indicators built into an intuitive touchscreen display.

- Remote hydraulic operation

- Safety lights and digital lock status

- Pressure-readouts per well

- Emergency shutdown function

- Off-site monitoring with secure cellular access

- All data stored, logged, and ready for review

FracLock: The Core Connection

A Safer, Smarter Way to Connect to the Wellhead

At the center of the system is the FracLock unit itself—a hydraulic, pressure-rated connection point designed to safely lock onto the wellhead without exposing the crew.

- 15,000 PSI working pressure

- 7″ internal diameter

- 130 BPM flow rate

- Four reactive wedges for full 360° contact

- Lock ring can’t release under pressure

- Sensor-integrated with remote visual lock indicators

It’s built simple, rugged, and smart. The lock ring can’t drop without a proper crossover or nightcap, and once you’ve got pressure on the well, it physically can’t lift. That’s safety built right into the metal.

Articulated Arm & Dynamic Flow Iron

Go Anywhere. Hook Up Fast. Get More Done.

The Articulated Arm extends out over 40 feet and reaches multiple wellheads from a single location. Five-axis movement and 360° rotation make it fast and flexible, without dragging extra iron all over site.

- Mounted on 53’ step-deck trailer

- 4 outriggers for max stability

- Remote or manual control

- 12 programmable well positions

- Auto and manual targeting

- C1D1 rated

Attached to the arm is the Dynamic Flow Iron—a 7” ID, 15K-rated powerhouse that was built to handle the real punishment. Every bend, elbow, and swivel is optimized to reduce erosion, prevent blowouts, and keep operations running longer without fail.

Data-Driven Durability

Tested for 3,960 hours. Erosion below 20%. No failures.

FHE has tested this system under load, under stress, and under fire. Simulation data, flow modeling, and hard run-time back it up. This system doesn’t just talk tough—it lives tough.

- 130 barrels per minute capacity

- Pressure-monitored lock integrity

- Real-time diagnostics from any location

- Predictive wear analysis for flow iron based on slurry and proppant data

Trained Operators. Certified Confidence.

Every crew running FracLock goes through FHE’s 40-hour certification program. Classroom instruction, hands-on rig-ups, and full testing ensure your team knows the system inside and out.

Every trained tech walks away certified, documented, and ready to run.

Ask us about our FracLock

Rental Program.

Get the performance without the commitment, and let us handle the upkeep. You get the gear, the support, and the results. We’ll take care of the rest.